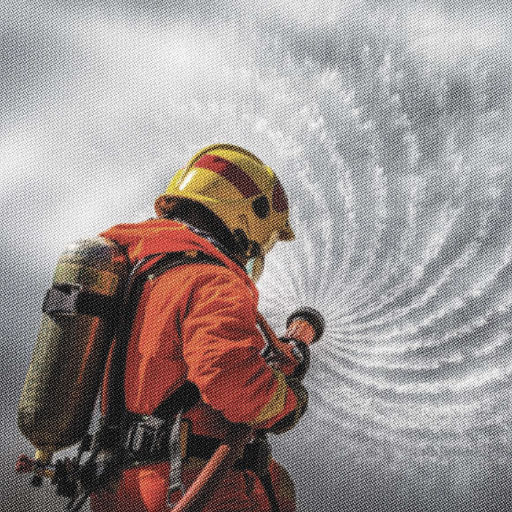

Foam Chamber

The foam system design guidelines generally used are in accordance with NFPA-11, standard. Foam Chamber is used in one of the most common applications to protect vertical fixed roof (cone) liquid storage tanks, with or without an internal floating roof with the low expansion foam system. The application of foam is on the basis that the risk comprises the total surface area of the fuel.

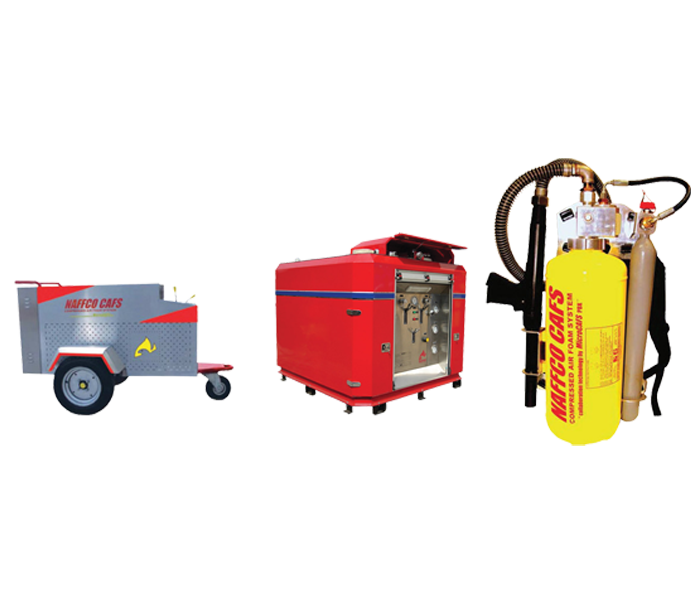

Foam chambers are defined by NFPA-11 as Type II discharge outlets for delivering the foam to the surface of a flammable liquid. The Foam Chambers are widely used with the In-line Foam Inductor, Balance Pressure Foam Proportioning system, Bladder Tank Proportioner, or Foam Tender.

Foam Chamber is an air aspirating foam discharge device, covering a wide range of flow from 40 GPM to 1086 GPM at 40 to 100 psi inlet pressure. The Foam Chamber contains a Vapor seal to prevent the entry of Vapor into the foam chamber and the foam solution pipe. Each foam chamber is supplied with an orifice plate, designed for the required flow and inlet pressure.