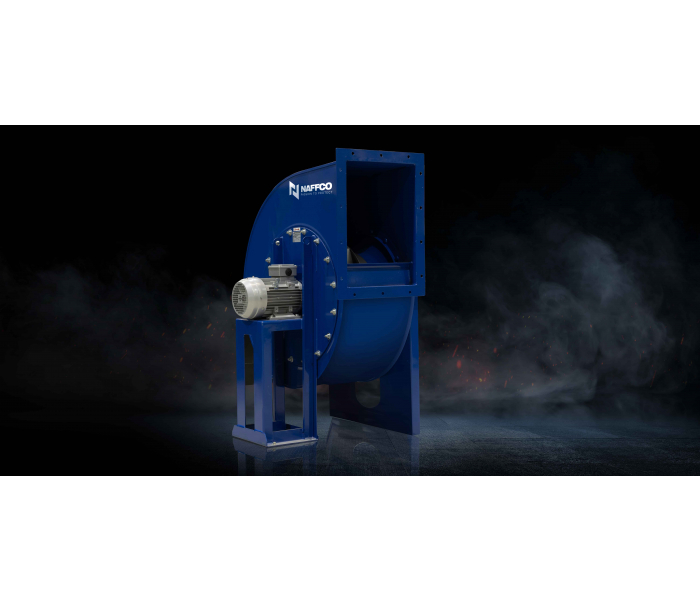

Centrifugal Backward Curved Blade Fans

APPLICATIONS

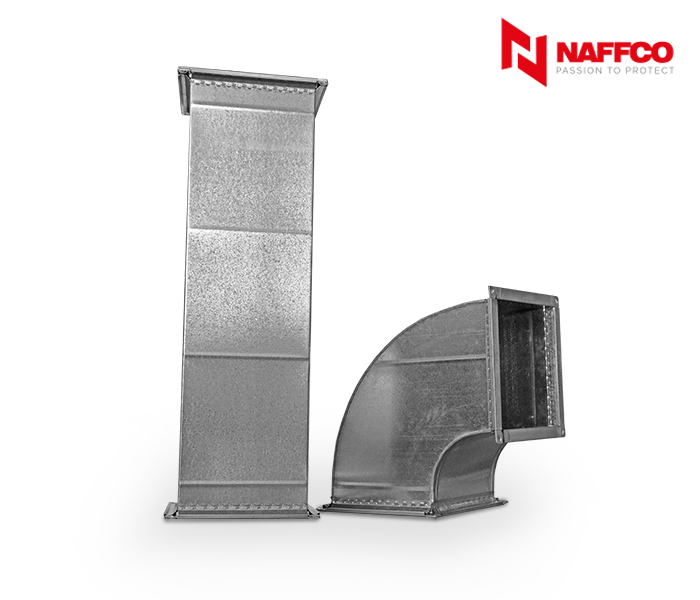

SI-BACK A fans are designed for installations requiring large air deliveries with relatively low pressures, in duct mounted applications. For instance: ventilation and conditioning of industrial and commercial plants, car parks, marine and mining applications, etc.

RANGE

This line consists of 15 sizes with impeller diameter from 250 up to 1250 mm.

- Rigid Construction In Enamelled Sheet Metal And The Thickness Of The Materials.

- Solution For Many Ventilation Problems, Explosion Proof Version (Atex Type)

- 150C Continuous Operation, Recommended For Kitchen Application

- Fans Scroll With Different Rotation Angles.

ADVANTAGES

SI-BACK A line is characterized by the extreme sturdiness due to the rigid construction in enameled sheet metal and the thickness of the materials. Another feature is the variety of models and versions composing the series, consenting to find the suitable solution for many ventilation problems. Impeller is available in different classes (I-II-III) according to the maximum RPM admitted for the relevant diameter.

CONSTRUCTION

- Volute in epoxy painted enameled steel sheet. Fixing flanges according to UNI EN ISO 13351/Tab.1 standards.

- High efficiency backward curved blade welded impeller.

Balancing according to UNI ISO 21940-11.

- Asynchronous three or single phase, electric motor, protection IP 55,insulation class F, service S1, mounting type B3 or B5, construction according to IEC / EEC (UNEL MEC).

- Arrangement 4 or 5 (impeller directly coupled to motor shaft); arrangement 1, 9, 12 (belt driven, with impeller coupled to the motor by mean of transmission).

TECHNICAL SPECIFICATIONS

SI-BACK A standard

- Conveyed air: clean, slightly dusty, not abrasive.

- Temperature of conveyed air: -20°C / +60°C.

- Voltage:

three phase version (T) 400V – 50Hz.

single phase version (M) 230V – 50Hz.

ARRANGEMENTS

- SI-BACK A arrangement 4: impeller directly coupled to motor shaft, motor placed on the motor support.

- SI-BACK A arrangement 5: impeller directly coupled to motor shaft, motor flanged on the fan volute.

- SI-BACK A arrangement 1: bare shaft version, basic arrangement for belt coupling (without any coupling component).

- SI-BACK A arrangement 9: belt coupling version, with motor placed on the side of the support (including belt drive kit and motor).

- SI-BACK A arrangement 12: belt coupling version, with motor and fan placed on a common basement (including belt drive kit and motor).

ACCESSORIES

- Inlet protection grid (IPG-SBA)

(Necessary for use in free air).

- Outlet protection grid (OPG-SBA)

(Necessary for use in free air).

- Inlet flexible joint (IFC-SBA).

- Outlet flexible joint (OFC-SBA).

- Inlet counter flange (ICF-SBA).

- Outlet counter flange (OCF-SBA).

- Inspection door (ID-SBA).

- AV mounts (AM).

- Condensation drain hole (CD).

ON REQUEST

- Explosion proof versions (SI BACK A Atex).

- Stainless steel versions.

- High temperature versions (150°C for direct coupling and 300°C for belt coupling versions).

|

Catalog |